No. 96, 6th Main, 1st Phase. Near Basaveshwara Circle, BEML Layout 3rd Stage, Rajarajeshwari Nagar, Bengaluru - 560098

Service Details

Explore the full scope, benefits, and features of our specialized service offerings — crafted with engineering precision and delivered with excellence.

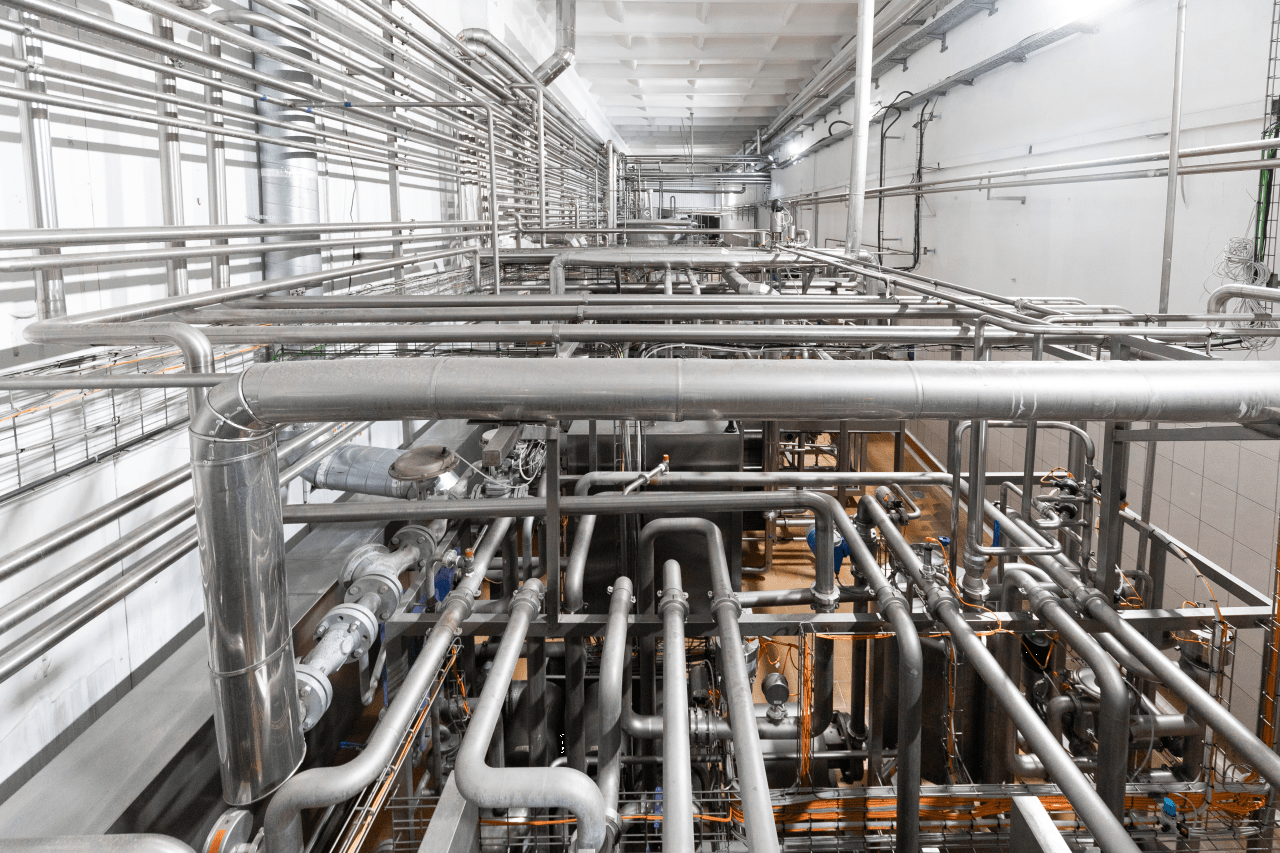

Industrial machinery piping works are a critical part of any industrial setup, facilitating the controlled transport of fluids, gases, steam, and chemicals within a facility. These systems form the circulatory network of industrial operations, connecting machinery, processing units, storage tanks, and utility stations.

Scope of Piping Works

Piping works in an industrial environment include the design, fabrication, installation, and testing of pipelines used across various sectors such as:

Manufacturing

Power Plants

Chemical and Petrochemical

Food & Beverage

Water Treatment

Pharmaceuticals

Oil & Gas

These systems serve multiple functions, including process piping, utility piping (air, steam, water), fire fighting lines, and hydraulic or pneumatic supply lines.

Key Elements of Industrial Piping

Pipe Material Selection: Based on fluid type, temperature, and pressure (e.g., carbon steel, stainless steel, HDPE, PVC)

Fabrication & Welding: Precision cutting, beveling, and welding to ASME/ANSI/API standards

Supports and Hangers: To ensure pipe stability and safety during operation

Valves and Fittings: Proper integration of isolation, control, and safety valves

Testing and Commissioning: Hydro-testing, pneumatic testing, and quality inspections for leak-proof performance

Advantages of Professional Piping Works

Operational Efficiency: Proper routing and installation ensure smooth flow and reduce energy loss.

Safety and Compliance: Adherence to international standards prevents leaks, corrosion, and potential hazards.

Longevity: Quality materials and expert fabrication enhance system durability and reduce maintenance costs.

Customization: Systems are tailored to suit the layout, machinery interface, and process requirements.